Online 24 hours a day

|

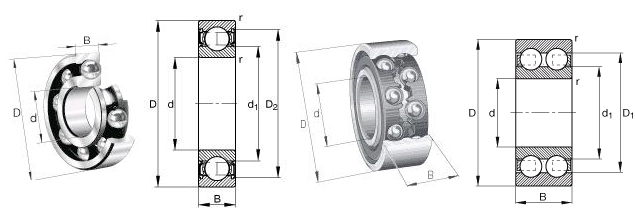

Deep groove ball bearing

Collect

Deep groove ball is a more common type of rolling bearing, the basic deep groove ball bearing by an outer ring, an inner ring, a set of steel balls and a set of cage composition, bearing type has a single row and double row two, deep groove ball structure is also divided into sealed and open two kinds of structure, open refers to the bearing without sealing structure, sealed deep groove ball is divided into dustproof seal and oilproof seal, dustproof seal cover material for steel plate stamping, only play Simple to prevent dust into the bearing raceway, oil-proof type for contact oil seal, can effectively prevent the bearing grease spillage. Single row deep groove ball bearing type code for 6, double row deep groove ball bearing code for 4. Its structure is simple, easy to use, is the production of common, widely used a class of bearings, deep groove ball bearing mainly bear radial load, but also can simultaneously bear radial load and axial load. When it only bear radial load, the contact angle is zero. When the deep groove ball bearing has a large radial clearance, with angular contact bearing performance, can withstand large axial load, deep groove ball bearing friction coefficient is very small, the limit speed is also very high. Deep groove ball bearing structure is simple, compared with other types of easy to achieve high manufacturing accuracy, so it is easy to series mass production, manufacturing costs are also low, the use of extremely common. Deep groove ball bearings in addition to the basic type, there are a variety of variant structure, such as: with dust cover deep groove ball bearings, with rubber seal deep groove ball bearings, deep groove ball bearings with stop groove, with ball loading gap of large load capacity of deep groove ball bearings, double row deep groove ball bearings. Deep groove ball bearings are representative rolling bearings for a wide range of applications, suitable for operation at high or even very high speeds, and are very durable and require no frequent maintenance. They have a low coefficient of friction, a high limiting speed, low manufacturing costs and are easy to manufacture to a high degree of precision. The size range and form of the variation, applied in precision instruments, low noise motor, automobile, motorbike and general machinery and other industries, is the machinery industry in the use of a more extensive class of bearings. |